The role of Aluminum Casting Company in streamlining manufacturing processes

Wiki Article

Discover Comprehensive Foundry Services for All Your Metal Casting Demands

The landscape of metal casting has progressed significantly, with considerable foundry services emerging as an essential resource for suppliers. These services encompass a variety of procedures, from pattern making to finishing techniques. By checking out the numerous offerings and technologies available, one can much better understand exactly how these remedies enhance performance and top quality. The implications of selecting the ideal provider, nonetheless, are significant and merit additional expedition.Recognizing Metal Casting Procedures

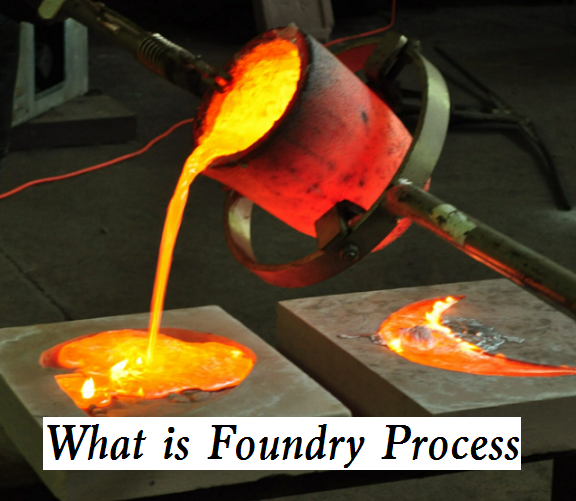

Metal casting is a basic process in manufacturing, where liquified metal is put right into a mold and mildew to develop wanted structures and shapes. This strategy has actually been utilized for centuries, allowing for the production of complex components across various industries. The process begins with the prep work of a mold and mildew, which can be made from products such as sand, metal, or ceramics, depending upon the preferred surface and application. Once the mold prepares, metal is heated up to its melting factor and afterwards very carefully gathered, making sure that it fills up all tooth cavities. After cooling, the solidified metal takes the form of the mold and mildew. The casting is after that gotten rid of and usually calls for ending up procedures, such as machining or polishing, to achieve precise measurements and surface area high quality. Recognizing these essential processes is essential for any individual entailed in the production and design sectors, as it lays the groundwork for reliable design and production.Kinds Of Foundry Services Offered

Foundries offer a diverse series of services customized to meet the particular demands of various markets. Amongst these services, pattern making attracts attention as an essential step, where mold and mildews are produced from products like wood or metal to form the end product. Additionally, metal putting is an essential service, including the transfer of molten metal into the ready molds.Foundries additionally provide finishing services, which include processes such as machining, brightening, and surface therapy to improve the last appearance and capability of cast parts. Quality control is one more important solution, making sure that the castings fulfill market criteria and specifications.

Many factories give engineering support, helping customers in layout optimization and material choice. This considerable technique permits foundries to accommodate fields such as automotive, aerospace, and building, making certain that they meet the varying demands of their clients effectively.

Benefits of Using Comprehensive Foundry Services

Utilizing substantial foundry services offers many benefits that significantly improve production efficiency and quality. By giving a one-stop remedy for numerous metal casting needs, these services improve the manufacturing process, reducing preparations and lessening the need for multiple suppliers. This incorporated method fosters far better interaction and coordination, allowing for extra accurate control over production timelines.Extensive foundry services frequently assure exceptional top quality with standard processes and skilled oversight. This uniformity assists in conference strict market laws Aluminum Casting Company and client requirements. Furthermore, the access to a varied series of materials and casting methods allows firms to choose the ideal remedies for their specific tasks.

Cost-effectiveness is one more substantial benefit, as packed services can result in economic climates of range. Ultimately, using thorough foundry services not only improves functional efficiency however additionally advertises development and versatility in item growth, making it a strategic choice for companies in the metal casting market.

Advanced Technologies in Metal Casting

As the metal casting industry evolves, the assimilation of innovative innovations plays a vital function in enhancing manufacturing abilities and high quality. Advancements such as computer-aided design (CAD) and computer-aided production (CAMERA) have changed standard methods, allowing for extra exact and efficient designs. Additive production, frequently called 3D printing, is transforming the prototyping procedure, making it possible for fast production of intricate geometries that were formerly challenging to achieve.In addition, automation and robotics enhance repetitive jobs, decreasing labor costs and decreasing human error. The fostering of simulation software application makes it possible for foundries to predict end results and enhance procedures, eventually leading to lowered waste and enhanced source administration. Innovations in products science add to the growth of new alloys and composites that improve efficiency and durability. Collectively, these technologies are not only improving operational effectiveness yet additionally positioning the metal casting industry for future growth and advancement.

Just how to Pick the Right Foundry Provider

Just how can one determine one of the most ideal foundry service provider for their particular needs? It is vital to evaluate the company's know-how and experience in the appropriate metal casting processes. This includes evaluating their capabilities in managing various materials and their knowledge with sector criteria.Next off, prospective clients ought to consider the company's technological capabilities. A foundry that utilizes sophisticated innovations can typically provide higher precision and efficiency. Additionally, evaluating the company's quality control procedures is critical; strong top quality control measures show a commitment to producing dependable items.

Taking a look at past customer reviews and instance studies can offer understandings into the supplier's performance and consumer complete satisfaction. Reliable communication and cooperation are important; a receptive and transparent service provider will certainly help with a smoother task. By systematically examining these elements, one can make an educated decision in choosing the right foundry service supplier.

Often Asked Concerns

What Products Can Be Utilized for Various Metal Casting Procedures?

Different products can be utilized in metal casting procedures, including aluminum, steel, iron, bronze, and magnesium - Precision aluminum casting. Each product has one-of-a-kind buildings, making it ideal for certain applications within the diverse range of casting techniques readily availableHow much time Does the Metal Casting Refine Normally Take?

The metal casting process normally takes a number of weeks, depending on variables such as complexity, manufacturing, and material volume. First style and mold development can considerably influence the general timeline before last casting and ending up.Exist Minimum Order Quantities for Foundry Services?

Several shops impose minimum order amounts to guarantee cost-effectiveness and performance in production. These amounts can vary based on the kind of metal, intricacy of the casting, and certain solution agreements with clients.Can Custom Layouts Be Fit in Metal Casting?

Yes, customized styles can be accommodated in metal casting. Foundries typically supply versatility to create special patterns and molds, making certain that particular customer demands are fulfilled while preserving high standards of top quality and precision.What Qualifications Should a Foundry Solution Supplier Have?

A respectable foundry company should possess accreditations such as ISO 9001 for top quality monitoring, ISO 14001 for environmental administration, and certain sector qualifications associated with safety and compliance, making sure adherence to finest methods and requirements.The landscape of metal casting has actually evolved significantly, with substantial foundry services arising as a crucial source for suppliers. Metal casting is a basic procedure in production, where liquified metal is poured into a mold and mildew to develop wanted forms and structures. Amongst these services, pattern making stands out as a vital action, where mold and mildews are developed from products like wood or metal to shape the last product. By offering a one-stop service for various metal casting needs, these services simplify the manufacturing process, minimizing lead times and lessening the demand for numerous providers - Precision aluminum casting. It is vital to examine the supplier's knowledge and experience in the appropriate metal casting processes

Report this wiki page